Load cells are transducers that are designed as measuring devices. They gauge and monitor forces of compression, tension, and shear by converting sensed mechanical force into measurable electrical signals. Often, you’ll hear the term “load cell” used interchangeably with “transducer,” “load sensors,” “sensor” or “gauge.” In some senses, these are different things, while in other senses, they are not. Read More…

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

We offer standard tension, standard compression, hollow tension/compression and many other types of load cells for your convenience of choice. Each of our load cells is designed to meet ASTM specifications and our customers’ requirements to further ensure the exact product for you! All of our products are put through extensive testing before leaving our state of the art facilities to ensure the ...

At P3 America, Inc., our expertise centers around delivering top-of-the-line load cell solutions meticulously designed to meet diverse industrial and weighing needs. We specialize in providing a comprehensive range of high-quality load cells crafted to suit various applications and client specifications. Within our portfolio of load cells, we offer a versatile array, including tension load cells, ...

More Load Cell Manufacturers

For example, sensors and gauges are a part of load cells. Yet, sensors are a type of transducer as well. You can see where the confusion comes in! So, while it is appropriate to call load cells and sensors both “transducers,” it’s less appropriate to call sensors and gauges “load cells.” Nevertheless, be prepared to see them used this way, and if you are confused, never hesitate to ask for clarification.

This technology is commonly employed for mechanical and industrial testing, ongoing system load monitoring, as components in devices like industrial scales and other areas of the manufacturing, processing, and testing industries.

Load cells, as well as pressure sensors and gauges, have a wide variety of specific applications. For example, warehouse workers use load cells to determine the exact weight of loaded pallets. In food processing, load cells and pressure sensors give a precise ingredient measurement and distribute them accordingly during packaging. Other applications include calibration systems, fatigue testing in research and development laboratories, push-pull testing and flow measurement, bridge beam tension strength testing, railcar weighing scales, and truck scales.

The History of Load Cells

Modern load cells work using strain gauges arranged in a Wheatstone configuration. We owe this technology to two innovations: the Wheatstone bridge equation and the strain gauge. The Wheatstone bridge equation, perfected and popularized in 1843 by a man named Sir Charles Wheatstone, demonstrates the concept of difference measurement. This equation wasn’t terribly useful until the strain gauge was invented. Until then, people weighed large loads and industrial items using mechanical lever scales.

The strain gauge was developed about 100 years later, in the 1940s. At that time, researchers developed the first bonded resistance wire strain gauge. Once the Wheatstone bridge equation and the strain gauge were united, load cells were born. Though engineers had the ingredients for load cells, they lacked the electronic technology and funds to produce them on a mass scale for many years. Once it became viable, the use of the load cells took off, and the industry is booming to this day.

Design

Production Process

Load cells are produced using the principles of mass measurement under fluid pressure, elasticity, magnetic effect, piezoelectric, and zero environments. They are composed of two basic parts: the sensing element and the circuit. They often also feature cables.

Most often, the sensing element is a strain gauge. Strain gauges are small devices that measure an object’s strain, weight, or force output by converting internal deformation into electrical signals. A less frequent companion of the load cell is the piezoelectric sensor, which utilizes piezoelectric crystals to measure strain, movement, weight, and vibrations. Two common sensors that fall under the piezoelectric umbrella are pressure and force transducers/force sensors. Similar to load cells, they measure applied force, pressure, and strain of gas pressure, liquid pressure, and altitude. The circuit connects the sensors or gauges to points throughout the load cell. Cables, if used, connect transducers to instrumentation.

Material Design

Load cells may be made up of a variety of different metallic materials, such as tool steel, alloy steel, stainless steel, and aluminum, depending on the goals of the load cell. Per the application, manufacturers seek out different material properties, like low weight, high strength, good electrical conductivity, good thermal conductivity, attractive appearance, easy machining, corrosion resistance, high cryogenic toughness, malleability, etc.

Design Considerations and Customization

When designing a load cell, manufacturers must think about a number of different things. First, they must consider and calculate the load cell potential capacity. They do so by considering system dynamics (frequency response), maximum force value, maximum extraneous load capacity and the effect of placing the transducer in the force path. For mounting the load cell, they must also think about whether it will be put directly or indirectly in the path of the primary load, the environment in which it will be placed (water, corrosion materials, etc.) and the size of the space measuring force load cell in place, to ensure the safety and productivity of the industries employing them. These considerations help them build a load cell of the right size, shape, material, and capacity for the job. To that end, manufacturers may customize load cells by shape and size.

Features

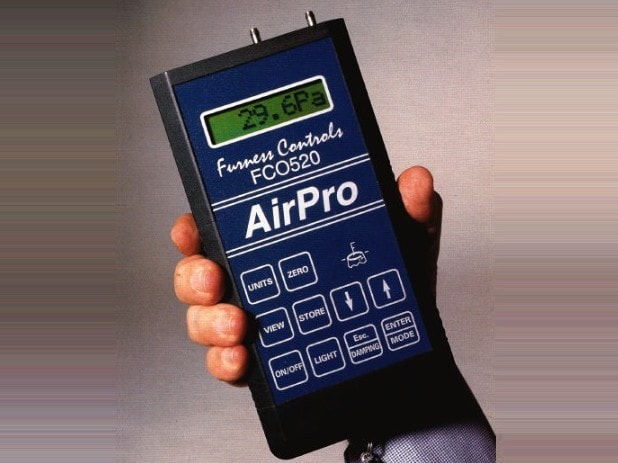

Load cells work using sensing devices, such as strain gauges, that measure force, pressure, etc. When sensing devices, whatever they may be, collect data, they send it on to a recorder or another computerized data collection system. These systems are either analog, which uses voltage, or digital. Of the two, digital load cells are more popular because they are faster, more accurate, and have better resolutions. If and when the systems discover any variance in the system they’re monitoring, load cells sound an alarm or shut down completely until the issue is understood and corrected.

Types

Tension Load Cell

Tension load cells are used to measure load cell tension in the form of pulling apart force along a single axis. This type of force is known as positive force. Typically, tension load cells work with strain gauges.

Compression Load Cell

A compression load cell measures straight line pushing force, a negative force, along a single axis. Like tension load cells, compression load cells usually use strain gauges. Because they engage in load cell compression, they are ideal for applications with limited space. In addition, they offer excellent long-term stability.

Strain Gauge Load Cell

“Strain gauge load cell” is an umbrella term that covers all of those load cells that use strain gauges as their sensing element. Strain gauges have a capacity rate between 5 N and upwards of 50 N, use high-res digital indicators and meet ideal force transfer standards. Because of their excellent qualities, strain gauge load cells are the most commonly used load cell type.

Beam Load Cell

A beam load cell, also known as a bending load cell or a bending beam load cell, is usually used for industrial weighing. With a low-profile structure, beam load cells are ideal for integration into restricted areas.

S-Beam Load Cell

S-beam load cells, or shear beam load cells, are members of the beam load cell family. In this context, “shear” refers to the force that divides an object along a plane parallel to opposing stresses within the load cells. They provide superior side load rejection, and, if they are compressed or under pressure, an output. Typical s-beam load cell applications include on-board vehicle weighing, silo weighing, tank weighing, and industrial floor scales.

Platform Load Cell

Platform load cells, also called single point load cells, are designed to collect accurate readings no matter the load position on the platform. They have and use just one operating load cell. Typically, this load cell type is used for individual device applications, like supermarket scales.

Multi-Load Cell Scale

Multi-load cell scales operate with a similar principle to platform load cells but work by taking readings from more than one point on the scale. They take extremely accurate readings.

Interface Load Cell

Interface load cells serve larger systems that constantly measure torque and force.

Hydraulic Load Cell

Hydraulic load cells measure the change in pressure of internal filling fluid, which they record as weight. Most often, hydraulic load cells are found weighing pressure changes fluid in bins, tanks, and hoppers.

Miniature Load Cell

Mini load cells, just as one might expect, are designed for use with small applications, where they take precise measurements. They are similar to low-capacity transducers, which are mini transducers that can gauge weights between .9 oz and 150 lbs.

Mid Capacity Load Cell

Mid capacity load cells, also known as mid capacity transducers, are capable of accurately measuring weights between 200 and 20,000 lbs. Typical applications for this load cell type include truck weighing scales, industrial scales, bolt force measurement machines, and extremely large platform scales.

High Capacity Load Cell

High capacity load cells can accurately measure any weight upwards of 25,000 lbs.

Wireless Load Cell

Wireless load cells are load cells that work without cables. They are instead monitored with wireless indicators. This makes load and force measurement easier, faster, and lowers maintenance costs.

Donut Load Cell

Donut load cells, or thru-hole load cells, are named after their shape; they’re smooth and round, with a hole in the middle that allows for bolts or parts. They measure compressive forces, most often of those in oil and gas applications.

Pin Load Cell

Pin load cells are a type of strain gauge load cell that use load measuring pins. Load measuring pins, or load pins, feature strain gauges installed inside a small bore that runs through their centers. These load cells allow them to sense force applied across them. Pin load cells are found in sheaves, pivots, bearing blocks, shackles, and anchors, as well as many underwater devices. They work well underwater because the load cell is well protected with stainless steel, cable, and end caps that hermetically seal it.

Dynamometer Load Cell

Dynamometer load cells use dynamometers, or dynos, to measure power, force, and torque. Dyno load cells are used mostly to measure the engine power output. They are quite expensive, though, and are so avoided unless absolutely necessary.

Piezoelectric Crystal Force Load Cell

Piezoelectric crystal force load cells, or piezoelectric load cells, are designed to measure force applied to crystalline materials. They are able to do this because whenever force is applied to a crystalline material, it generates an electric charge. The transducer measures the electric charges using a built-in amplifier, then converts those measurements into a digital signal, which goes to an indicator that an operator can read.

Specialty Transducer

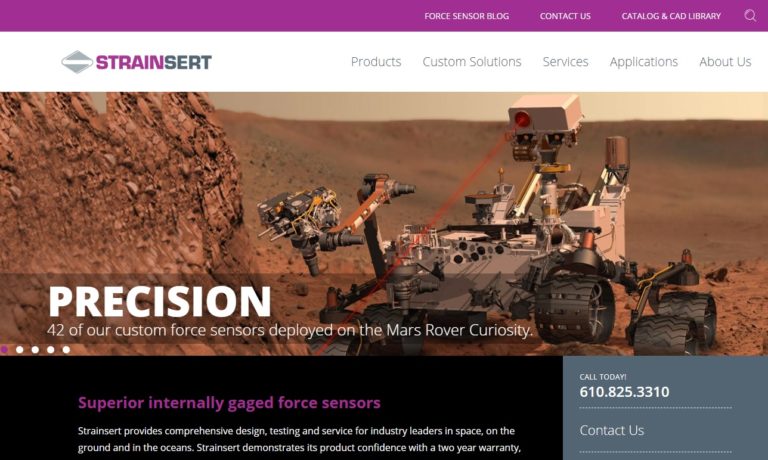

Specialty transducers are designed to measure in unique atmospheres, such as under the sea or out in space.

Torque Transducer

The term “torque transducer” applies to any load cell or other transducer that measures static and/or dynamic torque.

Tension Roll Transducer

Tension roll transducers are transducers used to measure tension in any continuous roll of paper, foil, textile, film, etc.

Absolute Pressure Transducer

Manufacturers design absolute pressure transducers/sensors to accommodate pressure increases. They do so by providing output voltage increases, generated with the assistance of a vacuum sealed or near vacuum sealed internal reference chamber.

Advantages of Load Cells

Load cells offer several advantages in various applications. First and foremost, load cells provide accurate and precise measurements of force or weight. They are designed to convert mechanical force into electrical signals, allowing for reliable and consistent measurements. This accuracy is crucial in industries such as manufacturing, agriculture, and logistics, where precise weight measurement is essential for quality control, safety, and efficiency.

Another advantage of load cells is their versatility. They come in various types and designs to accommodate different load capacities and environments. Whether it’s a small-scale laboratory application or a heavy-duty industrial setting, load cells can be customized to meet specific requirements. They can be used in tension, compression, or both, depending on the application. Additionally, load cells can be integrated into existing systems easily, making them adaptable to different setups and equipment.

Load cells also provide real-time monitoring capabilities. By connecting load cells to data acquisition systems or computer interfaces, it becomes possible to continuously monitor and record load measurements. This allows for immediate detection of any abnormal load variations, enabling proactive maintenance and preventing potential equipment failures or safety hazards.

Furthermore, load cells offer non-intrusive measurement. Unlike other methods that may require physical contact with the object being measured, load cells can measure the force or weight without direct interference. This feature is especially useful in delicate or sensitive applications where maintaining the integrity of the object is critical.

In terms of cost-effectiveness, load cells can prove to be beneficial as well. They have a long service life and require minimal maintenance. Once installed correctly, load cells can provide accurate measurements for an extended period with minimal calibration or adjustments. This reduces the need for frequent replacements or repairs, ultimately saving both time and money.

In summary, load cells provide accurate and precise force or weight measurements, versatility in different applications, real-time monitoring capabilities, non-intrusive measurement, and cost-effectiveness. These advantages make load cells indispensable in numerous industries, enabling improved quality control, safety, and efficiency in various processes.

Accessories

Load cells require very few accessories if any at all. Those they do use include load cell bases and load cell buttons. These accessories play a crucial role in optimizing the performance and functionality of load cells.

Load cell bases provide a stable and secure platform for load cells, ensuring accurate and reliable measurements. They are designed to minimize external disturbances and vibrations that could affect the load cell’s output. Load cell bases often feature a rigid construction with a low profile, allowing for easy installation and integration into existing systems. They come in different sizes and configurations to accommodate various load cell capacities and application requirements.

On the other hand, load cell buttons are accessories specifically designed for compression load cells. These buttons distribute the applied force evenly across the load cell, ensuring accurate measurement of compression forces. Load cell buttons are typically made of high-quality materials such as stainless steel to withstand high loads and maintain durability. They come in various shapes and sizes to match the load cell and application requirements.

Both load cell bases and load cell buttons contribute to the overall performance and accuracy of load cells. They provide stability, protect against external disturbances, and enhance the load cell’s ability to measure forces accurately. These accessories are essential in applications where precise and reliable force measurements are critical, such as material testing, industrial weighing systems, and force monitoring in research and development. By utilizing the appropriate load cell bases and load cell buttons, users can optimize the performance and ensure the longevity of their load cell systems.

Proper Care for Load Cells

Because they are so sensitive, it’s essential that you treat your load cells with great care. Below are a few pointers for load cell care:

- Never remove or tamper with sensor covers.

- Use a stable power supply in order to prevent high excitation voltage surges.

- To avoid putting undue stress on it, never yank, pinch, kink, or overbend a load cell cable.

- Keep a close eye on the temperature of the environment around your load cell, and make sure that it doesn’t exceed your load cell’s temperature tolerance range.

Standards

When you purchase a load cell, there are a few different safety and performance standards to which your transducer should comply. These include ISO standards and SAE AS9102 and/or ANSI/J-STD-001B standards. In addition, we recommend you double check that your load cell has been put through insulation resistance testing.

Other standard requirements vary by your region and industry. For instance, load cells to be used by NASA require NASA certification (NASA-STD-8739.3), and load cells to be used in the European Union must have and comply with RoHS certification.

Things to Consider

Before selecting or setting up a load cell for your application, you need to investigate a few factors, such as load cell capacity and load cell positioning. To calculate load cell capacity, make sure to consider the following maximum force value, the dynamics of the system (i.e. frequency response), the load cell’s response to the placement of a transducer in the force path, and how much extra weight the load cell can handle. Note that load cells can have between four and 30 gauges and that the more gauges inside the load cell, the greater the cell sensitivity in picking up and recording variances.

When you put the load cell into place, you must think about whether the load cell will be in the primary load path or whether it will measure forces remotely, as well as if there are any physical changes of the space that need to implemented for size and mounting, the level of accuracy required and what potential problems may arise from the environmental elements to which the load cell will be subjected. Consider these carefully, for accurate readings and load cell placement, greater safety on the factory floor, in the lab and beyond.

For the best results, you need to go with a high quality, trustworthy supplier. To find the right supplier for you, check out the many load cell manufacturers and distributors we have listed here. Look at the products, services, and pricing they offer. Choose three or four in whom you’re most interested, and then reach out to them for a quote and/or with your questions. Compare and contrast them, and choose the supplier that will serve you best.

Check out our Linear Actuators website

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services