They are used widely in mechanical testing, ongoing system monitoring, and as components in devices such as industrial scales. Read More…

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

Anyload has been in business for over 20 years. Anyload is experienced in the design and production of high quality standard load cells, specialty load cells, weigh modules, indicators, scales for commercial and industrial applications, and wide varieties of weighing components.

At Coti Global Sensors, we are dedicated to providing top-of-the-line load cell solutions and comprehensive services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted authority in load cell manufacturing, renowned for our commitment to quality, reliability, and customer satisfaction.

More Force Gauge Manufacturers

Load cells are in essence just another term for force gauges, which can be made up of two kinds of sensors, in a variety of industries. Any company that needs to measure heavy loads, such as pallets of goods for shipping in industrial manufacturing, building materials in construction, and mass amounts of ingredients or packaging in food processing companies, requires the use of these load cells.

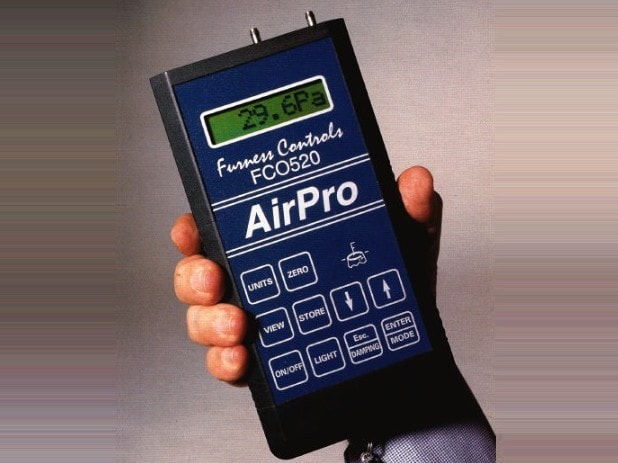

The two types of sensors utilized most often are strain gages and piezoelectric sensors, the first made up of metal coils and the second made up of crystals. They gather the information of force and translate it into electrical currents or signals that can then be read through analog or digital output.

Specifically, the strain gauges are deformed by the weight of the pressure, be it a separation stress like the tension load cell specializes in measuring, or a pushed together stress like the compression load cell is made to measure.

The crystals of the piezoelectric sensors are electrically neutral, but create a current when stress is applied. By gauging the amount of stress and the type of stress by the strength of the crystal reaction, a load cell or force gauge utilizing piezoelectric crystals can get a very accurate reading.

The main purpose of force gauges is to measure levelness and tension in load cells. The information they monitor is then signaled to a recorder or other computerized data collection system for further analysis.

The two basic components of a load cell are the sensing element and the circuit. The sensing element is often the force gauge and the circuit is the connection of these gauges throughout the load cell. Load cell outputs include analog voltage, analog current, analog frequency, switch or alarm, serial, and parallel.

The most basic designs consist of four gauges, which make up the measuring circuit. The connection between the four gauges is what makes up the circuit, which is also what connects to the analog or digital read out. More complex and detailed cells can have up to thirty gauges as part of the measuring circuit. The more gauges inside the load cell, the more sensitive the cell is in recording and monitoring variance in measurement.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

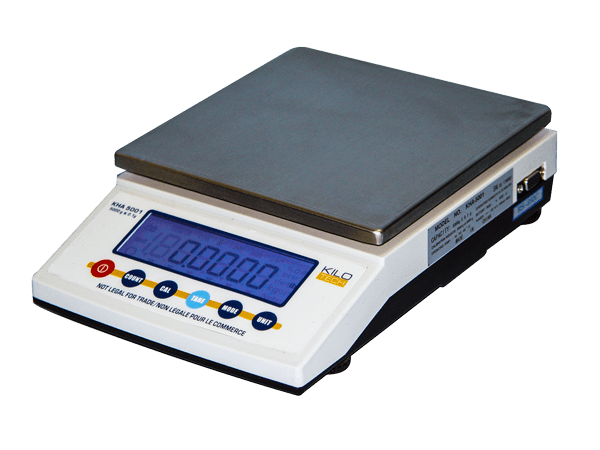

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services