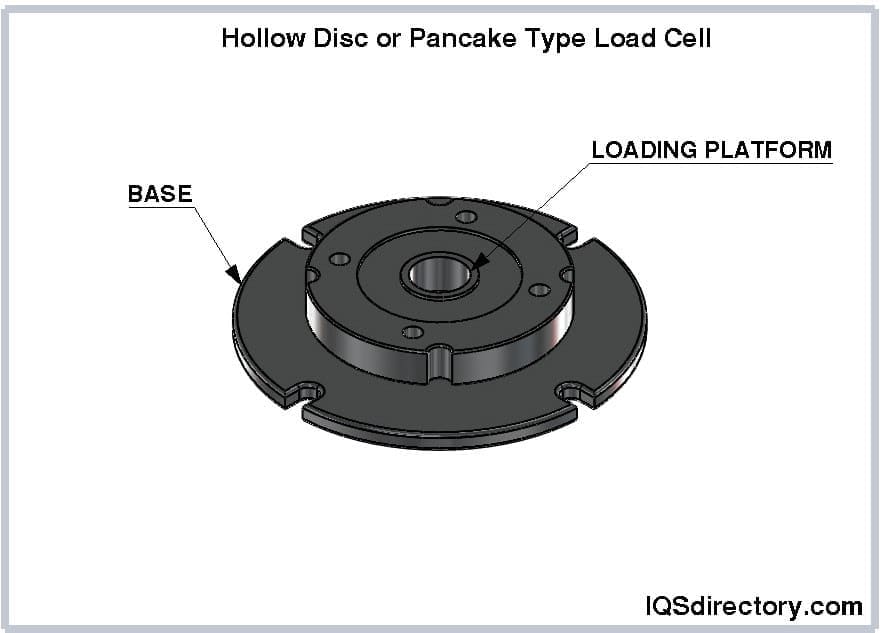

Pancake load cells have a symmetrical structure and are very compact. These load cells are also known as low-profile cells, and because of this low profile design it looks like a pancake. Pancake load cells can bear both tension and compression forces. Read More…

Our load cells are manufactured with the highest attention to detail at all stages. Whether it is through the design stage, engineering stage, or through hundreds of tests run daily, we ensure that our products outshine all competitor products.

Founded in 1985, Load Cell Central has firmly established its reputation as a leader in load cell manufacturing, custom weighing system integration, and first-class load cell repairs. Load Cell Central offers a wide variety of popular load cell and component configurations for virtually every new or old weighing system, scale or component replacement possibility. Technical and after-sale support, ...

At TyTek Industries we manufacture load cells to suit all capabilities. Our expertise has provided insight and load cell solutions for a range of customers and industries. Our engineering team’s philosophy ensures we do everything humanly and technologically possible to match your requirements with quality, cost and delivery. We’re here to help you carry the load.

Anyload has been in business for over 20 years. Anyload is experienced in the design and production of high quality standard load cells, specialty load cells, weigh modules, indicators, scales for commercial and industrial applications, and wide varieties of weighing components.

At Coti Global Sensors, we are dedicated to providing top-of-the-line load cell solutions and comprehensive services tailored to meet the diverse needs of our clientele. With years of experience and expertise in the industry, we have established ourselves as a trusted authority in load cell manufacturing, renowned for our commitment to quality, reliability, and customer satisfaction.

More Pancake Load Cell Manufacturers

These load cells are often used for push and pull applications in compartment scales, silo scales, machine scales, container scales, special scales, platform scale, truck scale, rail weighbridge, and as a tension tester in various industrial processes.

Structure of Pancake Load Cells

- Pancake load cells are made of stainless steel or aluminum material.

- Pancake load cell is a hole-structured elastic element.

- The whole structure of these load cells looks like a wheel. Spokes are formed between the hubs and tires which are symmetrically and mutually distributed.

- The hub, spoke, and tire make multiple shear beams with fixed supports on both sides.

Characteristics of Pancake Load Cells

- The external load is exerted on the upper end face of the wheel hub.

- The whole-structured elastic element has a low appearance and good stability.

- This structure is insensitive to the bending moment and also has good linearity.

- The transverse stiffness is large and the resistance to loads is also strong.

- The integrated structure of the pancake load cells is symmetric.

- The thermal expansion in different directions is also consistent with each other.

- The temperature coefficient of these cells is small.

- The hole-structured elastic element adopts the simple drilling process.

- The strain area is at the pure-shear stress state, which makes the root part with a small concentration.

- This makes the pasting position of the resistance strain gauge more reasonable.

- These types of load cells are ideally suitable for long-term use.

- These cells work in harsh conditions and give precise and reproducible measurements and results in push-pull applications.

Pancake Load Cells Series

PNC770 and PNC772 Series

- This series is a low-profile pancake cell and is designed for tension and compression application.

- These force transducers are made of aluminum and suitable for weight-limited applications.

- The PNC770 uses integral cable, while PNC772 is designed with a bolt-on flange electrical connector.

- This series is also shock and vibration resistant.

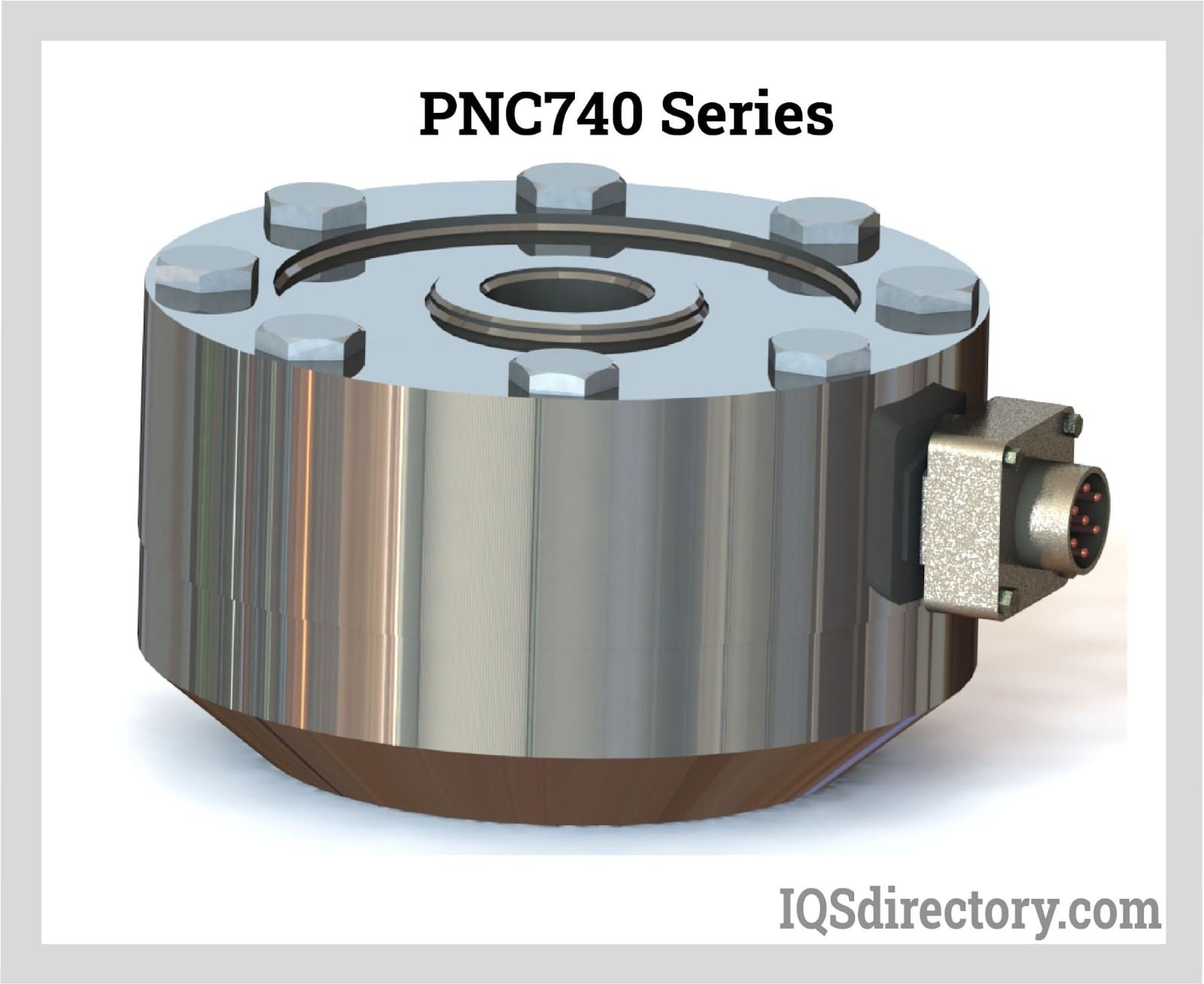

PNC760 and PNC740 Series

- The PNC760 and 740 series are fatigue low-profile load cells.

- They are configured both for tension and compression applications.

- The PNC760 and 740 series give high accuracy and low off-axis sensitivity.

- The PNC760 series is made of high strength alloy steel with bolted-on stainless steel electrical connectors.

- O-ring steel and gold plated pins are also present.

- An optional base plate is also present to give more rigidity and a good mounting.

- The PNC740 series is made of welded stainless steel.

- Both series have shock and vibration resistance.

PNC720 and PNC710 Series

- The series PNC720 is a low-profile pancake designed for compression force application.

- The PNC720 series have an integral spherical load button and also welded diaphragms. These features are for improved accuracy and rigidity.

- The PNC720 and PNC710 series are made of welded stainless steel for a very demanding application environment.

- PNC710 is a high accuracy low-profile pancake design.

- It is used for both tension and compression applications.

- The PNC710 series has a threaded-through center hole with two diaphragms.

- The diaphragms are welded to the sensing section and the mounting outer section.

- The rigidity of the series increases by reducing the effects of both off-center loading and side loading.

- The PNC710 series load cells have shock and vibration protection as well as barometric compensation.

- The PNC710 series is designed to be universally interchangeable within industry.

PNC700 Series and Coiled Tubing

- The PNC700 series is a highly accurate low-profile pancake design.

- It is used for both tension and compression forces.

- The structure is made of welded stainless steel with a threaded-through center hole.

- The PNC700 series have vibration and shock resistance and also barometric compensation.

- Coiled tubing injectors are low-profile designs.

- The coiled tubing is used for tension and compression forces with a 4-20mA output.

- The coiled tubing load cell consisted of a threaded-through center hole with a dual diaphragm which reduces off-axis sensitivity, and also improves rigidity and accuracy.

- The body of coiled tubing is made of stainless steel to meet the demands of both onshore and offshore oil and gas applications.

- These are designed to replace hydraulic load cells without redesigning the injector.

- Other features are shock and vibration resistance.

Applications of Pancake Load Cells

- Pancake load cells are used in weighbridge and lorry weighing scales.

- They are also used in car weighing scales, tanks, and silo weighing scales.

- Pancake load cells are also used for measurement of press-in and insertion forces.

- Pancake load cells are also used in spring forces, cutting forces, force measurement, and control during assembly.

- It is also used in measurement of pressure on drilling machines.

Pros and Cons of Pancake Load Cells

Pros of Pancake Load Cells

- The pancake load cells are strong, have resistance performance, and lateral loading capacity.

- These load cells are not affected by the loading point and supporting edge.

- These load cells have a good linearity and can be fixed at one place.

Cons of Pancake Load Cells

- The mechanical processing of pancake load cells is difficult.

- Pancake load cells have a high manufacturing cost.

- It has a great inherent lag and is also difficult to control.

Choosing the Right Pancake Load Cell Manufacturer

To ensure the most positive outcome when purchasing pancake load cells from a pancake load cell manufacturer, it is important to compare several companies using our directory of pancake load cell manufacturers. Each pancake load cell manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each pancake load cell business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple pancake load cell companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services